Beginning the Hinge

We make several sizes of hinges in the butterfly or dovetail style. These are cut for us out of mild steel plate (16 gauge) by a company with a laser. We originally cut these ourselves by hand with a shear and hacksaw but found that the laser cut hinge parts were more precise and allowed quicker fitting.

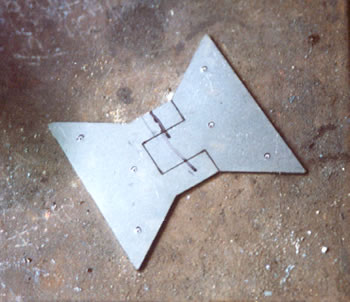

The Blank

This is a laser cut blank with the center punched marks for the holes already made. The laser cutting has both pieces held together by a thin sliver of steel. After punching, we break the two pieces apart.

Punching the Holes

We use a large "hand punch" to punch out the holes in the mild steel.

Molly and the Punch

The punch that Molly is using is a Whitney number 8. This punch is capable of punching a 1/4" hole through a piece of 1/4" thick mild steel. It is held in the vise while Molly is using it. A punch goes just below the cam in the top, and a die is held at the bottom. We have a number of different punches and dies.

Starting the Eye

The hinge part is heated in the forge and then moved quickly to a swage block where the curve for the start of the eye is formed using a small hammer peen.

The metal because it is so light cools very quickly while working.

Starting the Eye

Here is a hinge half with a started eye.

Making a Latch

is a description, with photos, of the steps we go through to make a Suffolk Latch.

Making a Hinge

is a description, like Making a Latch, that shows the steps we go through to make a Butterfly Hinge.

Making a Grip

shows the process for making a Cabinet Grip.

Blacksmith's Blog Posts

collects posts we created for the Horton Brasses blog in 2010 and 2011. There's information about the shop, what we make and how we make it, including links to two videos.

Tools of the Trade

shows some of the tools in Molly’s blacksmith shop.

Making a Living

describes how we became blacksmiths.

Glossary of Blacksmithing Terms

is linked to various words that are not commonly known by non-smiths throughout this section of the site.