Finishing the Hinge

When the hinge is ready, a hot finish of beeswax and raw linseed oil is used. The hinge is examined when cool and sometimes has to be reheated, wire wheeled and refinished if there are scale “pops.” The scale is what gives the hinge its black finish when the oil and wax are applied. If scale is popped, that area will show as a shiny silver spot.

Pre-Heating the Hinge

The hinge is heated slightly so that the finish will cover every part.

Hinge in Finish

The raw linseed oil and beeswax mixture forms a paste when cool. The hot hinge will sink into this paste and become covered.

Warming the Finished Hinge Again

After being dipped in the finish, the hinge is again held over the fire so that the hot finish will reach every pore of metal.

Cooling the Hinge

The hinge is laid onto a large steel “bowl” to cool. When cool enough to touch the extra finish is wiped off. After two days the hinge receives its final hand waxing with Johnson's Paste Wax.

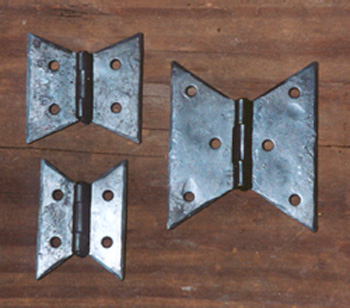

Finished Hinges

Here are three different sizes of butterfly hinges.

Go back to Hinge Introduction.

Making a Latch

is a description, with photos, of the steps we go through to make a Suffolk Latch.

Making a Hinge

is a description, like Making a Latch, that shows the steps we go through to make a Butterfly Hinge.

Making a Grip

shows the process for making a Cabinet Grip.

Blacksmith's Blog Posts

collects posts we created for the Horton Brasses blog in 2010 and 2011. There's information about the shop, what we make and how we make it, including links to two videos.

Tools of the Trade

shows some of the tools in Molly’s blacksmith shop.

Making a Living

describes how we became blacksmiths.

Glossary of Blacksmithing Terms

is linked to various words that are not commonly known by non-smiths throughout this section of the site.