|

|

|||

| First | Previous | Next | Last | Introduction |

Beginning the forging

We forge the latches in a coal forge, heating the mild steel to about 1800°. The metal cools quickly while under the hand hammer and some processes require several heats. Our tools are simple, a coal forge with a hand operated blower, a 2 pound hammer (we use several styles depending on the effect needed), tongs that hold the stock, vise and our anvil, in this case weighing about 150 pounds. The forge, anvil and vise are placed close together. The vise is a 180° turn from the forge. The anvil, between the forge and vise, is one step away from the forge.

During the initial stages of forging we use an additional tool called a blacksmith helper, or guillotine swage. We are able to use different dies, and a gauge to help position stock, to achieve different aims. During the beginning of the forging we use the blacksmith helper to set out the amount of stock for the top and bottom cusps.

Heats 1 & 2

We use the blacksmith helper to fuller the stock to separate the material used for the cusp from the material used for the grip part of the latch.

Heats 1 & 2

The first heat is finished. The stock is forged behind the fullered mark into the grip area. The piece of original sized stock is shown. We use a piece of mild steel that is 1/4 inch thick, 3/4 inches wide and 7 inches long. If we were making a bean latch the stock would be 6 inches long.

Heat 2

The stock is being forged at the other end in the grip section of the bar.

Heats 3 & 4

We’ve upset the material for the cusp, driven it back onto itself while hot, holding it in the vise, so that it will be thicker. This will give us more metal when spreading the cusp.

The piece to the left has been upset, the piece on the right is original size.

Heats 5

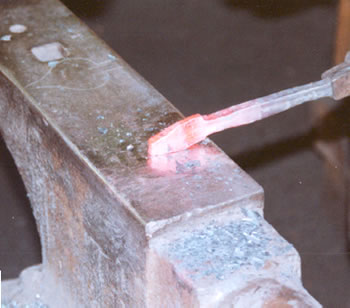

To start to create the heart shape on the cusp we put a point on the end of the cusp portion of the stock after upsetting it. This photo shows the point about half way through the heat. The stock will be drawn to a sharper point.

Making a Latch

is a description, with photos, of the steps we go through to make a Suffolk Latch.

Making a Hinge

is a description, like Making a Latch, that shows the steps we go through to make a Butterfly Hinge.

Making a Grip

shows the process for making a Cabinet Grip.

Blacksmith's Blog Posts

collects posts we created for the Horton Brasses blog in 2010 and 2011. There's information about the shop, what we make and how we make it, including links to two videos.

Tools of the Trade

shows some of the tools in Molly’s blacksmith shop.

Making a Living

describes how we became blacksmiths.

Glossary of Blacksmithing Terms

is linked to various words that are not commonly known by non-smiths throughout this section of the site.